T-34-85 – the military designation of the last mass modification of the Soviet medium tank T-34 with an 85-mm caliber gun. Adopted by the Red Army by GKO Decree No. 5021 of January 23, 1944.

Designed on the basis of the serial T-34 tank of the 1942 model. The installation of an 85 mm gun and design improvements significantly increased the combat effectiveness of the T-34-85 tank compared to the T-34-76.

Designed on the basis of the serial T-34 tank of the 1942 model. The installation of an 85 mm gun and design improvements significantly increased the combat effectiveness of the T-34-85 tank compared to the T-34-76.

The new turret of increased volume with enhanced armor protection is structurally similar to the turret of the experimental T-43 tank. The overall security of the crew (5 people) has been increased, the conditions for the functional interaction of crew members have been improved. Mobility indicators (speed, maneuverability and maneuverability) of the T-34-85 tank decreased slightly due to an increase in its combat weight.

In the spring and summer of 1944, the stabilizer of an 85-mm tank gun was tested in a vertical plane. This stabilizer was developed by a special design bureau of the People’s Commissariat of Shipbuilding under the leadership of A. Atovmyan on the subject of “Battering Ram”. Its design features are that the gyroscope, spun by a three-phase asynchronous motor, was not located on the gun, but controlled the power supply circuits of the hydraulic drive pump of the power unit. To power the gyroscope, a GKZ-T DC converter is installed based on a 24 V DC electric motor and a three-phase network generator with a voltage of 60 V and a frequency of 275 Hz. The power consumption of the stabilizer is 550 W, the startup time is 4.5 minutes. The first tests of the prototype took place in March-April 1944 in Kubinka.

Since 1944, the T-34-85 was the main tank of the Red Army in the Great Patriotic War.

With a slightly increased, thanks to the tower, overall armor protection (compared to the T-34-76 tank), but insufficient, in comparison with the heavy tanks of the enemy, the T-34-85 tank practically did not lose its former mobility and maneuverability – the main advantage of a medium tank in duels with tanks “Tiger” and “Panther”. As a combat vehicle, the T-34-85 tank was a classic example of a combination of design and technological solutions, which together ensured the best compliance with the tactical and technical requirements for a “cruising” tank at the final stage of the Great Patriotic (and World War II) war.

The T-34-85 was produced in the USSR from January 1944 to 1950 – before the start of mass production of the T-54. Under license from the USSR, 3185 tanks of this type were produced in Czechoslovakia in 1952-1958 and 1980 tanks in Poland in 1953-1955.

In total, almost 30.5 thousand T-34-85 tanks (including those produced in Czechoslovakia and Poland) were produced, and taking into account the previously released T-34-76 tanks, the total output amounted to just over 65.8 thousand. This allows us to assert that the T-34 tank is the most massive tank in the world.

After the war, the T-34-85 formed the basis of the tank forces of the Soviet Army until the mid -1950s, until the mass receipt of the newest medium tanks T-54 in the tank forces of the Soviet Army. Officially, the T-34-85 was decommissioned by the Armed Forces of the Russian Federation in 1993.

After the war, T-34-85s were delivered in significant quantities to the states of Europe and Asia, where they were used in armed conflicts, including the Korean and Six-Day Wars and a number of others. As of 2007, the T-34-85 was still in service with a number of countries.

History of T-34/85 Creation

At the end of 1942, the latest German tanks and self-propelled guns with enhanced armor protection and powerful long-barreled weapons arrived on the Eastern Front.

From April 25 to April 30, 1943, at the NIIBT test site (Kubinka), an 85-mm anti-aircraft gun 52-K pierced the 100-mm frontal armor of the captured Tiger tank from a distance of 1000 m. The ballistic characteristics of the 52-K anti-aircraft guns were taken as the basis for designing the 85-mm D-5 tank gun, taking into account the reduction in terms for mastering the production of shells. Initially, the D-5 gun, which has a relatively large breech, was intended in the D-5S variant for the SU-85 self-propelled guns based on the T-34 tank and in the D-5T variant for the KV-85 and IS-1 heavy tanks. Until the autumn of 1943, the GABTU and the NKTP did not consider the possibility of using an 85-mm gun for a serial medium tank T-34 and a promising experimental medium tank T-43.

From April 25 to April 30, 1943, at the NIIBT test site (Kubinka), an 85-mm anti-aircraft gun 52-K pierced the 100-mm frontal armor of the captured Tiger tank from a distance of 1000 m. The ballistic characteristics of the 52-K anti-aircraft guns were taken as the basis for designing the 85-mm D-5 tank gun, taking into account the reduction in terms for mastering the production of shells. Initially, the D-5 gun, which has a relatively large breech, was intended in the D-5S variant for the SU-85 self-propelled guns based on the T-34 tank and in the D-5T variant for the KV-85 and IS-1 heavy tanks. Until the autumn of 1943, the GABTU and the NKTP did not consider the possibility of using an 85-mm gun for a serial medium tank T-34 and a promising experimental medium tank T-43.

The Soviet medium tank T-34 with a 76-mm F-34 cannon retained its superiority over the enemy in speed, maneuverability and maneuverability, but was significantly inferior to the Tiger, Ferdinand and Panther in armor protection and armament. In the summer of 1943, during an oncoming tank battle near Prokhorovka, the T-34 tank had to first overcome the “dead” zone and get as close as possible to the enemy at a striking distance of its gun. In fact, a very unfavorable situation has developed for the armored forces of the Red Army. People’s Commissar V. A. Malyshev received a reprimand from the Supreme Commander I. V. Stalin. At the organizational level, all conceivable and unthinkable measures were taken. The design bureau of plant No. 183, which was in charge of the T-34 tank, ruled out the possibility of installing an 85-mm gun on an experimental T-43 tank. There remained the only option acceptable for wartime conditions – the installation of an 85-mm gun on a serial T-34 tank.

In 1944, the T-34-85 was put into mass production. The crew increased from 4 to 5 people. The new turret with reinforced armor and increased volume was more comfortable for the crew and the tank commander. The combat weight of the vehicle increased by several tons, which led to a slight decrease in maneuverability and maneuverability.

Armor slope effect

The analysis showed that the slope of the armor contributes to the ricochet of shells only in the case when the caliber of the shell does not exceed the thickness of the armor, that is, in this case, for calibers less than 45 mm. With an increase in caliber, the probability of a ricochet from an inclined sheet quickly decreases. For shells of 88 mm caliber, the slope of the T-34 armor had practically no effect on armor penetration. However, the effect of the given thickness value works for any caliber and the normalization of shells when penetrating at an angle of 60° does not exceed two degrees. That is, a sheet located at an angle of 60° to the vertical is actually equivalent to a double-thickness sheet: 1/cos(60°)=2, which makes it possible to cover internal volumes more rationally, reducing the total armor mass. That’s whyslanted armor plates are sometimes used in modern tank layouts.

The analysis showed that the slope of the armor contributes to the ricochet of shells only in the case when the caliber of the shell does not exceed the thickness of the armor, that is, in this case, for calibers less than 45 mm. With an increase in caliber, the probability of a ricochet from an inclined sheet quickly decreases. For shells of 88 mm caliber, the slope of the T-34 armor had practically no effect on armor penetration. However, the effect of the given thickness value works for any caliber and the normalization of shells when penetrating at an angle of 60° does not exceed two degrees. That is, a sheet located at an angle of 60° to the vertical is actually equivalent to a double-thickness sheet: 1/cos(60°)=2, which makes it possible to cover internal volumes more rationally, reducing the total armor mass. That’s whyslanted armor plates are sometimes used in modern tank layouts.

Creating a new tower

At the end of August 1943, People’s Commissar for Tank Building V. A. Malyshev, Marshal of the Armored Forces Ya. N. Fedorenko, and senior officials of the People’s Commissariat of Arms arrived at Plant No. 112 (Gorky). At a meeting with the leaders of the plant, Malyshev said : “The victory in the Battle of Kursk came to us at a high price. Enemy tanks fired at ours from a distance of 1,500 m, while our 76-mm tank guns could hit Tigers and Panthers at a distance of 500-600 m. Figuratively speaking, the enemy has arms one and a half kilometers, and we are only half a kilometer. It is necessary to immediately install a more powerful gun in the T-34.

Initially, it was supposed to consider on a competitive basis the option of installing an 85-mm gun with anti-aircraft ballistics, D-5T, on a T-34 tank, which by this time had been successfully used on heavy tanks KV-85, IS-1 and on SU-85, based on tank T-34, in the D-5S variant. However, taking into account the dimensions of the D-5T gun, it was necessary to design a new, more spacious turret for it. In this regard, the chief designer of the TsAKB, V. G. Grabin, proposed the option of upgrading the T-34 to install his own, more compact S-53 gun, in the standard turret of the serial T-34 tank (model 1943), and submitted his project for approval People’s Commissar for Armaments D. F. Ustinov and People’s Commissar for Tank Building V. A. Malyshev. The project involved the start of production of prototypes at the plant number 112. In the S-53 cannon, pre-war design solutions developed for the F-30 cannon, designed for the design heavy tank KV-220, were implemented. However, V. A. Malyshev and many specialists from the Scientific Tank Committee (NTC) and the People’s Commissariat of Arms questioned the merits of the Grabinsky project. By order of V. A. Malyshev, the head of the tower group of plant No. 183, M. A. Nabutovsky, with a group of specialists, urgently flew to plant No. 112 to figure everything out.

Initially, it was supposed to consider on a competitive basis the option of installing an 85-mm gun with anti-aircraft ballistics, D-5T, on a T-34 tank, which by this time had been successfully used on heavy tanks KV-85, IS-1 and on SU-85, based on tank T-34, in the D-5S variant. However, taking into account the dimensions of the D-5T gun, it was necessary to design a new, more spacious turret for it. In this regard, the chief designer of the TsAKB, V. G. Grabin, proposed the option of upgrading the T-34 to install his own, more compact S-53 gun, in the standard turret of the serial T-34 tank (model 1943), and submitted his project for approval People’s Commissar for Armaments D. F. Ustinov and People’s Commissar for Tank Building V. A. Malyshev. The project involved the start of production of prototypes at the plant number 112. In the S-53 cannon, pre-war design solutions developed for the F-30 cannon, designed for the design heavy tank KV-220, were implemented. However, V. A. Malyshev and many specialists from the Scientific Tank Committee (NTC) and the People’s Commissariat of Arms questioned the merits of the Grabinsky project. By order of V. A. Malyshev, the head of the tower group of plant No. 183, M. A. Nabutovsky, with a group of specialists, urgently flew to plant No. 112 to figure everything out.

In October 1943, to speed up the work on linking the 85-mm gun in the turret of the T-34 tank, on the initiative of V. A. Malyshev, the turret group of plant No. 183, headed by Nabutovsky, was sent to the TsAKB. Nabutovsky arrived at Malyshev, and he ordered to organize a branch of the Design Bureau of Plant No. 183 at the artillery plant, at which Grabin’s TsAKB worked. After a short collaboration with Grabin, Nabutovsky was sent to the Design Bureau of F. F. Petrov. As a result, a joint conclusion was made that in order to install the S-53 and D-5 guns on the T-34 tank, a new, more spacious turret with a broadened shoulder strap is required. At a special meeting in the presence of D. F. Ustinov, Ya. N. Fedorenko and V. G. Grabin, M. A. Nabutovsky made a counter proposal to design new towers for the T-34 tank for arranging S-53 and D-5T guns in them based on the design of the turret of an experimental medium tank T-43, the project of plant No. 183. M. A. Nabutovsky criticized the idea of V. G. Grabin. From the speech of M. A. Nabutovsky: “Of course, it would be very tempting to put a new gun in a tank without significant alterations. This solution is simple, but absolutely unacceptable for the reason that with such an installation of the gun, its fastening will turn out to be weak, a large unbalanced moment will arise. In addition, this creates cramped quarters in the fighting compartment and significantly complicates the work of the crew. Moreover, when shells hit the frontal armor, the gun will fall out. Nabutovsky said:”By accepting this project, we will bring the army down.” The ensuing silence was broken by Grabin: “I am not a tanker, and I cannot take into account everything. And for the implementation of your project, it will take a lot of time, a decrease in production. Ustinov asked: “How long does it take to submit the design bureau of plant No. 183 for approval at this meeting?” Nabutovsky asked for a week, the director of plant No. 112, K. E. Rubinchik, provided him with all his design bureaus. Ustinov also scheduled the next meeting in three days. A. A. Moloshtanov came to the aid of M. A. Nabutovsky.

When designing, the 3-seat turret of an experimental T-43 medium tank was taken as a basis. The variant design of turrets for the 85-mm gun based on the 3-man turret of the T-43 tank was started at the same time: Design Bureau of Plant No. 112 “Krasnoe Sormovo” headed by V. V. a group of plant No. 183, headed by A. A. Maloshtanov and M. A. Nabutovsky, for the 85-mm gun S-53. Within three days of round-the-clock work, the technical documentation for the turret for the S-53 gun was ready.

As a result, two new turrets were designed for the T-34 tank, very similar to each other, resembling, but not copying, the turret of the experimental T-43 tank, with a shoulder strap diameter of 1600 mm.

In October 1943, the TsAKB Order was issued (Chief Designer V. G. Grabin) “On the development of a special 85-mm gun for the T-34 tank”.

In October 1943, the D-5T gun, installed in the new turret of plant No. 112 on the T-34 tank, was tested:

To better balance the trunnions of the guns, they were significantly moved forward, however, the breech of the gun was located very close to the rear of the turret, which made it difficult for the loader to work. Even when the tank was moving at low speed, trained loaders could not avoid collisions between the head of the projectile and the breech of the gun. The D-5T gun took up a lot of space, so only two people could be accommodated in the new turret. As a result, the D-5T gun was not accepted into service with the T-34 tank.

— M. Baryatinsky

In October-November 1943, following the order of the NKV to create an 85-mm gun for the T-34 tank, TsAKB and Plant No. 92 produced three prototypes of new tank guns: S-53 (leading designers of the TsAKB: T. I. Shabarov); S-50 (leading designers of the TsAKB: V. D. Meshchaninov, V. A. Tyurin, A. M. Volgaevsky); LB-1 (LB-85) (factory No. 92, designer A. I. Savin). During the tests, which continued until the end of 1943, preference was given to the S-53 gun.

The S-53 gun favorably differed in its simplicity of design, reliability and compactness, it made it possible to accommodate three crew members in a new, more spacious turret. The recoil brake and knurler are located under the base of the bolt, which made it possible to reduce the height of the line of fire and increase the distance between the breech and the rear wall of the tower. The production cost of the S-53 gun turned out to be even lower than for the 76-mm F-34 gun, not to mention the D-5T.

— M. Baryatinsky

In early December 1943, plant No. 112 sent two experimental T-34 tanks with new turrets to the Moscow Artillery Plant, where they installed S-53 guns and carried out mostly successful tests, during which flaws in its design appeared. In this regard, at the artillery plant number 92 during the next meeting with the participation of D. F. Ustinov, V. A. Malyshev, B. L. Vannikov, Ya. N. Fedorenko, F. F. Petrov, V. G. Grabin and others, it was decided to put the D-5T cannon on the Sormovo T-34 tanks for the time being and at the same time refine the S-53 cannon.

– The serial production of the S-53 cannon was supposed to be deployed at plant No. 92 from March 1, 1944, and until then, plant No. 112 Krasnoye Sormovo was allowed to install the D-5T gun in the new turret designed by plant No. 112.

– According to the plan, plant No. 112 was supposed to produce 100 T-34 tanks with a D-5T gun by the end of 1943, that is, before the official adoption of the T-34 tank, with an 85-mm gun in a new turret, into service. However, the first cars were produced only at the beginning of January 1944.

– Plant No. 112 “Krasnoye Sormovo” was asked to: ensure the production of T-34-85 tanks with a D-5T gun in quantities: in January 1944 – 25 units; in February 1944 – 75 units; in March 1944 – 150 units; from April 1944 – completely switch to the production of T-34-85 tanks, instead of T-34-76.

On January 1, 1944, the S-53 gun was adopted by the T-34 tank with the possibility of its installation in towers with both a regular shoulder strap (1420 mm) and an extended shoulder strap (1600 mm).

In January 1944, Moloshtanov and Nabutovsky, with all the documentation on the layout of the new S-53 gun in the new turret for the T-34 tank, arrived at plant No. 183.

When creating the D-5T tank gun and the S-53, which won the competitive tests, the ballistics of the 85-mm anti-aircraft gun 52-K of the 1939 model was taken as the basis. The 52-K anti-aircraft gun during test firing, which took place from April 25 to April 30, 1943 at the NIIBT training ground in Kubinka, pierced the 100-mm frontal armor of the captured Tiger from a distance of 1000 m. The development of a new tank gun based on the 52-K anti-aircraft gun reduced the time for mastering the production of shells.

Due to the individual characteristics of the production of different factories and depending on the time of production, the turrets of the T-34-85 tanks, equipped with the S-53 and ZIS-S-53 guns, differed in: the number, configuration and location of the molding and welds; the shape of the commander’s turret (in January 1945, only a single-leaf hatch cover for the commander’s turret was put into production); the shape and location of the protective strips of the turret. The post-war towers of factory No. 112 had a spaced arrangement of ventilation hoods, the front fan was an exhaust fan, the rear one was a pressure fan.

Mass production

1943

December 1943

Plant No. 112 has begun preparations for serial production of the T-34 tank with the D-5T gun in the new Sormovo turret.

1944

January 1, 1944

The T-34 tank was armed with the S-53 cannon with the possibility of installation in towers, both with standard (1420 mm) and extended (1600 mm) diameters of turret shoulder straps (GKO Decree No. 4873, dated January 1, 1944 ).

January 23, 1944

The T-34-85 tank was adopted by the Red Army (GKO Decree No. 5020 ss, dated January 23, 1944). In this regard, all T-34 tanks with a 76-mm gun produced in 1944 and previous releases received the designation T-34-76.

Plant No. 112 produced the first 25 T-34-85 tanks with the D-5T gun in the new Sormovo turret.

February 1944

Plant No. 112 produced 75 T-34-85 tanks with a D-5T gun.

Plant No. 112 began a gradual transition to the production of T-34-85 tanks with the S-53 gun.

When the S-53 cannon was first installed in the Sormovo turret, it became clear that the turret needed to be improved in order to increase the lower elevation angle.

March 1944

The production of S-53 guns in the commissioning mode has begun.

Plant No. 112 produced 150 T-34-85 tanks with the D-5T gun, completed the production of the T-34 and began mass production of tanks with the S-53 gun.

March 15, 1944

Plant No. 183 (UTZ) produced the first T-34-85 tanks with the S-53 gun.

April 1944

Plant No. 112 produced the final batch of T-34-85 tanks with the D-5T gun – 5 tanks.

In total, from January to April 1944, plant No. 112 produced 255 T-34-85s with a D-5T gun, of which 5 tanks were command tanks, with an RSB-F radio station.

First half of 1944

Serial production of medium tanks T-34 continued to carry out: plant number 112 “Krasnoe Sormovo”; Ural Heavy Engineering Plant (UZTM), Sverdlovsk; No. 183 “Name of the Comintern”, Nizhny Tagil; Plant No. 174, Omsk.

Lead for the production of T-34-85 tanks in 1944-1945. was Plant No. 183. The Stalingrad Tractor Plant (STZ) did not resume tank production; The Ural heavy engineering plant “Uralmash” (UZTM) in Sverdlovsk produced exclusively self-propelled guns based on the T-34 tank; The Chelyabinsk Kirov Plant (ChKZ), Chelyabinsk, completed the production of T-34 tanks and completely switched to the production of heavy tanks and self-propelled guns based on them.

| Manufacturer | Armament | January | February | March | April | May | June | July | August | September | October | november | December | Total |

| No. 112 (Bitter) | D-5T | 25 | 75 | 150 | 5 | 255 | ||||||||

| No. 183 (Nizhny Tagil) | ZiS-S-53 | 150 | 696 | 701 | 706 | 711 | 714 | 723 | 724 | 727 | 731 | 6583 | ||

| No. 112 (Bitter) | 28 | 291 | 300 | 315 | 315 | 315 | 315 | 315 | 315 | 315 | 2824 | |||

| No. 174 (Omsk) | 13 | 93 | 146 | 198 | 200/10 | 200/10 | 150/10 | 1000/30 | ||||||

| Total | 25 | 75 | 328 | 992 | 1001 | 1034 | 1119 | 1175 | 1236 | 1239/10 | 1242/10 | 1196/10 | 10662/30 |

Note: in the numerator – total, in the denominator – including TO-34-85

| Manufacturer | Armament | January | February | March | April | May | June | 3rd quarter | 4th quarter | Total |

| No. 183 (Nizhny Tagil) | ZiS-S-53 | 750 | 750 | 740 | 730 | 715 | 625 | 1898 | 1148 | 7356/91 |

| No. 112 (Bitter) | 300 | 300 | 315 | 315 | 315 | 315 | 795 | 600 | 3255/55 | |

| No. 174 (Omsk) | 140/15 | 150/40 | 200/30 | 175/30 | 200/40 | 200 | 475 | 400 | 1940/155 | |

| Total | 1190 | 1200 | 1255 | 1220 | 1230 | 1140 | 3168 | 2148 | 12551/301 |

Note: in the numerator – total, in the denominator – including TO-34-85

274 “commander” tanks with the RSB-F radio station were included in the number of produced at the plant No. 112 T-34-85 (1944 – 5 D-5T, 129 – ZiS-S-53; 78 of them were handed over in June)

1946

A total of 2701 T-34-85s were produced.

- Plant No. 183 – 493;

- Plant No. 112 – 1154;

- Plant No. 174 – 1054.

The total release amounted to 25,914 tanks.

Design features of wartime production tanks

In the T-34-85 tank, the quality and reliability of components and assemblies reached the highest level, while the design and layout retained exceptional manufacturability, high maintainability, quick recovery and commissioning of tanks damaged during hostilities.

The structural and weight reserves for further increasing the combat effectiveness of the T-34-85 tank were far from being completely exhausted. In particular:

- the torsion bar suspension of the road wheels was not implemented, by analogy with the experimental T-43 tank and the serial T-44, which would provide: improved dynamic characteristics of the vehicle; an increase in the volume of the fighting compartment due to the elimination of side shafts of spring shock absorbers for the suspension of road wheels.

Note: The serial medium tank T-44 was a symbiosis of the serial T-34-85 and the experimental T-43. Strengthening the armor protection of the hull of the T-44 tank, in comparison with the T-34, was achieved, in particular, due to: reducing its building height; the elimination of fender niches, which means by reducing the useful volume of the hull, offset by a decrease in the number of crew members.

In the process of serial production, the factories made changes to the design of the T-34-85 tanks to reduce production costs, increase reliability, combat survivability and combat effectiveness.

- As production progressed, the shape and size of the beam of the bow of the hull, connecting the upper and lower frontal plates, changed, and on machines of later releases it was completely withdrawn – the upper and lower frontal plates were butt-welded.

- During 1944, the following were introduced: fastening of five spare tracks on the upper front plate of the hull; hinged box front mudguards; installation of small smoke bombs (MSH) on the aft hull sheet.

Serial tanks T-34-85 (like their predecessors, T-34) built by different factories, with absolute unification of components and parts, at the same time had minor, individual – factory, design differences due to local technological features of production. In particular: various options for mounting spare fuel tanks on the sides of the hull; various options for the protective strips of the turret; in the undercarriage, road wheels were used only with rubber tires (the shortage of rubber was eliminated thanks to supplies from the USA), both stamped and cast, with developed ribs and lightening holes; various options for caterpillar tracks; gun turrets differed in the configuration and location of welded and molded seams, the number and location of viewing devices, ventilation fungi, and mounting assemblies; brackets-handrails;

Tanks T-34-85 with a gun D-5T built by the plant number 112 “Krasnoe Sormovo” had the following design features:

- the mask of the gun at the base of the barrel is cylindrical, the width of the embrasure window is less, a telescopic articulated sight TSh-16 was installed, there was no electric drive for turning the turret.

- The trunnions of the cannon cradle have a large forward offset relative to the axis of rotation of the turret, the commander’s turret is shifted forward, there is no antenna output on the roof of the turret, and only one ventilation fungus was installed on the first turrets.

Since March 1944, Plant No. 112 began to produce T-34-85 tanks with the S-53 gun, while the first tanks had external features similar to tanks with the D-5T gun. In particular, the configuration of the early Sormovo tower, U-shaped mounting eyes, the location of fuel tanks, etc..

In December 1944, Plant No. 112 submitted a number of proposals to the GABTU to improve the layout of the turret. In particular:

- on the replacement of the 2-leaf commander’s hatch with a single-leaf;

- about the introduction of a frameless ammunition rack for 16 shots in the niche of the tower;

- about duplication of control of the rotation of the tower;

- on improving the ventilation of the fighting compartment by spreading the fans by moving one of the two towers installed in the rear of the roof to its front. At the same time, the front fan was an exhaust fan, and the rear one was a pressure fan;

In January 1945, of the above proposals from Plant No. 112, only a single-leaf hatch cover for the commander’s cupola was introduced.

Tanks T-34-85 with spaced fan mushrooms on the tower were produced exclusively by factory number 112 after the war. There was no viewing slot on the right side of the hull.

Licensed production at factories in Poland and Czechoslovakia.

In the late 1940s in accordance with the decision of the governments of Poland and Czechoslovakia, to assist in the development of serial production of T-34-85 tanks, design and technological documentation, technological equipment, equipment were transferred from the USSR, Soviet specialists were seconded. In 1949, the ČKD Plant (Prague) acquired a license for the production of the T-34-85 tank and the SU-100 self-propelled guns. In 1951, the Polish plant Bumar Labedy, located in the city of Gliwice (Poland), acquired a license for the production of the T-34-85.

In the late 1940s in accordance with the decision of the governments of Poland and Czechoslovakia, to assist in the development of serial production of T-34-85 tanks, design and technological documentation, technological equipment, equipment were transferred from the USSR, Soviet specialists were seconded. In 1949, the ČKD Plant (Prague) acquired a license for the production of the T-34-85 tank and the SU-100 self-propelled guns. In 1951, the Polish plant Bumar Labedy, located in the city of Gliwice (Poland), acquired a license for the production of the T-34-85.

The T-34-85 tanks of Polish and Czechoslovak production had minor design differences. Serial production was carried out: in Poland for 5 years; in Czechoslovakia for 6 years. By May 1, 1951, the first 4 Polish T-34-85s were assembled, some of the components and assemblies for them were delivered from the USSR. From 1952 to 1956, 1380 cars were produced in Poland.

The first T-34-85s in Czechoslovakia were assembled partly from components supplied from the USSR. The first tank was assembled on September 1, 1951, eight more tanks were completed before October. The tanks assembled in the shortest possible time under pressure from the USSR were subjected to a series of tests. During these tests, some failures occurred due to the poor quality of the production of the first tanks (in particular, steering, clutch, drives and electrical equipment). However, despite these shortcomings, the government gave the tank a green light, and mass production at the CKD in Sokolov began in February 1952 and continued until December 1953. At the same time, a government decision was made to transfer the production of tanks from Sokolov to Martin. The first tank of completely Czechoslovak production was made in the winter of 1952.

In total, 2736 T-34-85 tanks were produced in Czechoslovakia in 1951-56, taking into account special vehicles (VT-34 engineering vehicles, JT-34 cranes, MT-34 bridge layers, PBCHT-34 evacuation vehicles and PB-34 heavy bulldozers) – 3185. Early series tanks had flaws (for example, gearboxes remained problematic for many years, their quality in the early years was lower than the same Soviet-made units). All tanks produced in 1955-56 were exported. A total of 1,437 tanks were delivered to the Czechoslovak army, and 1,299 were exported. In the last three years, the quality of production has improved significantly, and some improvements have been made. Tanks were exported mainly to Egypt (820) and Syria (120), Romania and Bulgaria, as well as to other countries such as India, Iraq and Yemen. Cuba received 100 tanks (probably

In 1953, Polish T-34s were upgraded twice and designated T-34-85M1 and T-34-85M2 respectively. During the modernization, a preheater was installed; the engine was adapted to operate on various types of fuel; installed devices that facilitate the management of the tank; changed the location of the ammunition; a remote control system for a course machine gun was installed, which made it possible to reduce the number of crew members to 4 people; scuba diving equipment installed. In the PNR, on the basis of the T-34 tank, several samples of engineering and repair and recovery vehicles were developed and produced.

Design features of the Polish-made T-34

- other location of ammunition – 55 shots;

- the number of crew members is reduced to 4 people thanks to the new system of aiming and loading the frontal machine gun;

- additional mechanisms have been installed to facilitate tank management;

- equipment was installed to ensure the overcoming of water barriers along the bottom;

- slightly changed the configuration of the tower;

- increased the angular speed of rotation of the tower, up to (25÷30)°/sec;

- installed: another radio station – “10RT-26E”; another tank intercom – TPU-47; other surveillance devices for the commander – TPK-1 or TPK-U25;

- installed a night vision device for the driver;

- the volume of additional fuel tanks has been increased, providing an increase in the cruising range up to 650 km;

- the engine is adapted to operate on various types of fuel, equipped with a heater that facilitates starting at low temperatures.

Design features of the T-34 Czechoslovak production

- Slightly different turret configuration;

- The casting quality of the turret is noticeably higher than that of Soviet-made turrets;

- A different shape and location of additional fuel tanks;

- A different form of armor plates for exhaust pipes;

- Telephone connection port with an armored plate in the rear part of the left side;

- Headlight guard;

- Beamless nose of the hull.

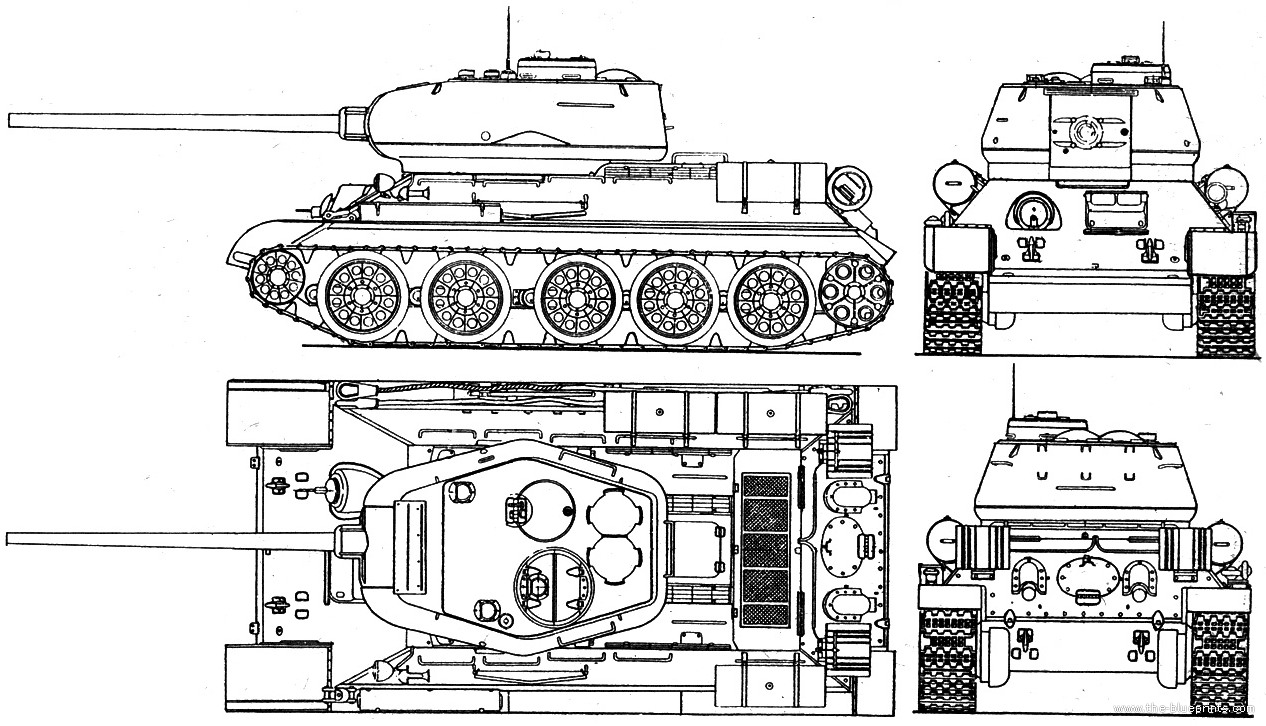

Technical description of the T-34-85 tank

With the adoption of the final modification of the T-34-85 tank, all T-34s produced in 1940-1943. received a single military designation T-34-76. Unlike its predecessor T-34-76, the T-34-85 with the S-53 gun (ZIS-S-53) had a three-man oversized turret (the shoulder strap diameter was increased from 1420 to 1600 mm), which made it possible to increase the volume of the fighting compartment, place a more powerful gun, an additional crew member and relieve the tank commander from the role of a gunner for more efficient coordination of the crew’s actions.

With the adoption of the final modification of the T-34-85 tank, all T-34s produced in 1940-1943. received a single military designation T-34-76. Unlike its predecessor T-34-76, the T-34-85 with the S-53 gun (ZIS-S-53) had a three-man oversized turret (the shoulder strap diameter was increased from 1420 to 1600 mm), which made it possible to increase the volume of the fighting compartment, place a more powerful gun, an additional crew member and relieve the tank commander from the role of a gunner for more efficient coordination of the crew’s actions.

The first tanks T-34-85 built by the plant number 112 “Krasnoye Sormovo” With the D-5T gun, they had a two-man turret, which was somewhat different in design from the turret developed by plant No. 183. The D-5T gun took up a lot of space, which did not allow placing an additional loader.

The body of the tank T-34-85

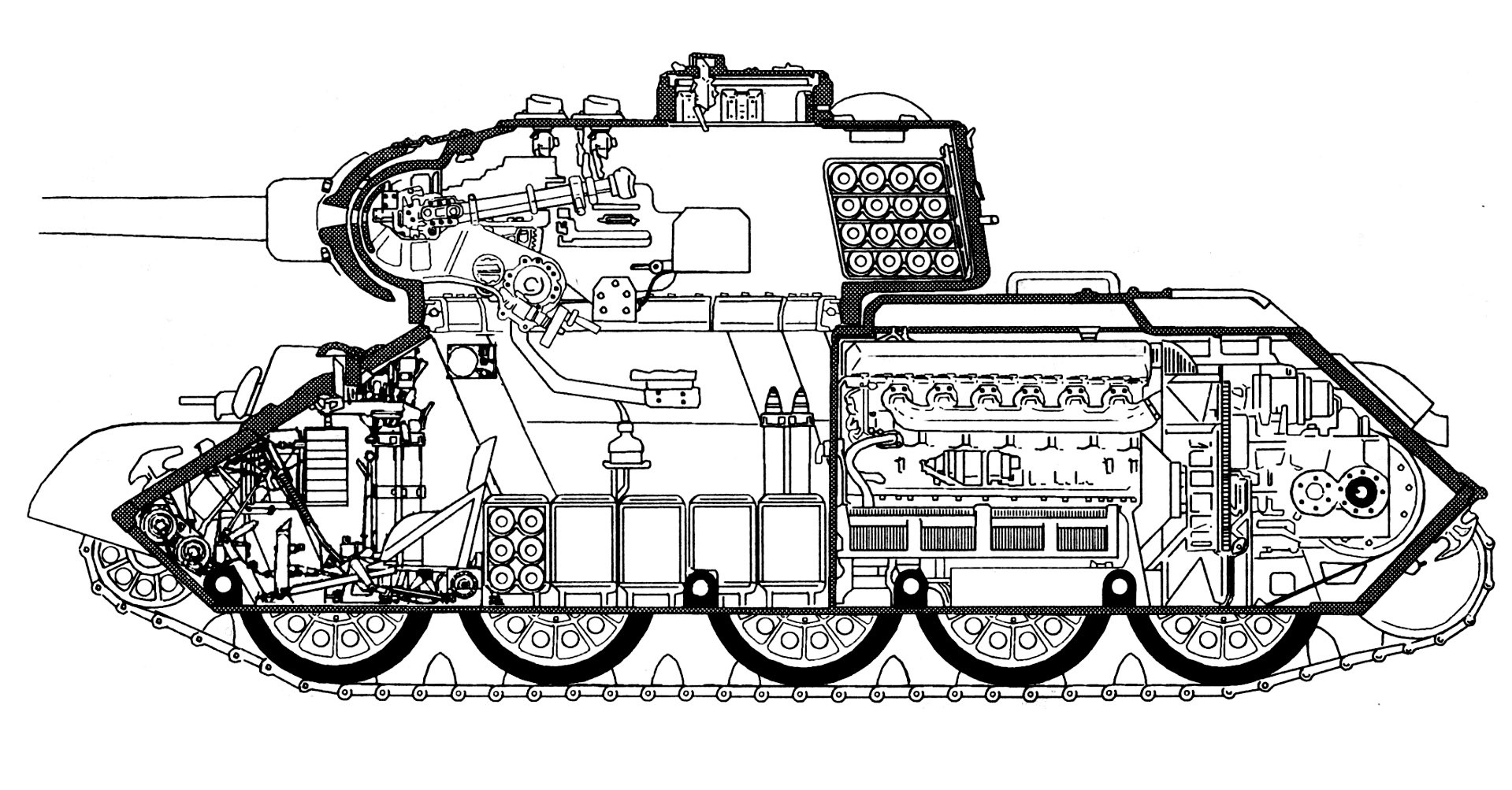

Case layout

The internal volume of the hull is conditionally divided into four sectional compartments: the control compartment in the front of the hull; fighting compartment in the middle part of the hull; power plant compartment in the rear of the hull; power transmission compartment in the aft part of the hull. The fighting compartment, compartments of the power plant and power transmission are separated from one another by removable steel partitions.

The management department houses :

- The driver is on the left and the machine gunner is on the right;

- height-adjustable driver’s seat and machine gunner’s seat;

- levers and pedals of drives for controlling units and systems of the power plant and power transmission; control and measuring devices that control the operation of the engine and electrical equipment.

- devices that control the operation of the engine and electrical equipment;

- frontal machine gun in a ball mount; part of the ammunition; first aid kit; ZIP.

- two cylinders with compressed air for air start of the engine;

- part of the ammunition;

- two hand-held carbon dioxide fire extinguishers;

- first aid kit;

- spare parts attached (SPTA).

In front of the driver are located: two cylinders with compressed air for air start of the engine; control panel; left and right control levers; transmission link; handle for manual fuel supply; fuel pedal; brake pedal with latch; main clutch pedal.

To the left of the driver, on the side wall, an electrical panel is installed, on which are located: an electric starter start button; tachometer ; speedometer. Two manual carbon dioxide fire extinguishers are fixed under the electrical panel.

In the fighting compartment of the hull and in the armored turret are placed:

- Along the course of the tank, to the left of the gun, the gunner, followed by the tank commander; to the right of the gun – loader;

In the fighting compartment of the corps are located:

- at the bottom there is a nozzle heater of the heating system;

- in the boxes fit the main part of the ammunition;

- along the bottom of the fighting compartment (under the boxes of ammunition) are the traction drives for controlling the mechanisms of the tank.

- on the sides of the fighting compartment section, behind vertical bulwarks made of sheet steel, there are lower, between the shafts of spring shock absorbers of the track roller suspensions, and upper fuel tanks.

In the department of the power plant are located:

- in the middle of the compartment, along the longitudinal axis, there is an under-engine frame for mounting the “V-shaped” diesel engine “V-2 “;

- on the sides of the engine are water radiators, batteries, oil cooler – mounted on the left water radiator, oil tanks and medium fuel tanks.

- in the roof of the power plant compartment there is a hatch for access to the engine and a hatch for the passage of air to the radiators – an air intake closed by shutters;

- tank control rods pass along the bottom of the compartment.

In the power transmission department are located:

- power transmission units;

- electric starter;

- two air cleaners and aft fuel tanks.

- in the roof above the power transmission compartment, an air vent hatch is made, closed by blinds with a grid;

- the upper aft armor plate is made folding, has a hatch for access to power transmission units.

- the box for tools and spare parts is installed on the horizontal shelf on the starboard side.

Hull design

The hull of the tank is welded and consists of the following main parts: frontal part; boards; aft; bottoms and roofs.

The armor plates of the hull are made of rolled armor, interconnected by electric welding, have thicknesses and angles of inclination, respectively: upper frontal – 45 mm, 60 °; lower frontal – 45 mm, 53 °; upper stern – 45 mm, 48 °; lower stern – 45 mm, 45 °; upper side – 40 °. The front sheet of the bottom is 20 mm thick, the rest – 13 mm. The roof is 20 mm thick.

Frontal part of the body. Consists of upper and lower frontal armor plates.

It is noteworthy that, as the T-34-85 tanks were produced, the bow hull beam connecting the upper and lower frontal plates decreased in size, and was removed on later production vehicles – the upper and lower frontal plates were welded end-to-end.

On the upper frontal sheet, on the right, a loophole for a ball mount of a frontal (course) machine gun was cut and armor protection (an armor cap of the loophole) was welded, on the left, a hatch was cut for the entry and exit of the driver, closed by a lid. In the cover of the driver’s hatch, two windows are made for the installation of viewing observation devices, closed with armored covers, opened by a mechanical drive from the inner handle. Threaded holes are made on the sides of the tow hooks, closed with armored plugs on the thread. Through these holes, access to the shanks of the “worms” of the track tensioning mechanism is provided.

Hull sides. They consist of lower vertical and upper inclined armor plates, to which horizontal shelves (elytra) are welded. Horizontal fenders are welded to the lower sides of the inclined armor plates, from the outside, which, together with the horizontal shelves of the hull, form mud-proof wings, serve as a place for the location of spare parts boxes and support for paratroopers.

On the fender of the left side there is a box with tools and spare parts for the gun.

On the starboard fender: a box for tools and spare parts is installed; fixed spare tracks for caterpillars; one or two towing ropes have been laid.

On the left inclined armor plate of the hull are installed: in front – brackets for the headlight and signal typhon; in the stern – brackets for attaching two spare, unarmored tanks, one for fuel, the other for oil.

On the right inclined armor plate of the hull are installed: in front – a radio antenna output bracket; in the stern – brackets for attaching two spare unarmored fuel tanks.

The fuel and oil in spare, unarmored fuel tanks are used up before the tank enters combat.

In each lower vertical sheet, holes are made for the passage of torsion axles of the suspension of the balancers of the track rollers, cutouts for the pins of the balancers. On the outer sides, brackets are welded to the lower vertical sheets for attaching rubber stops that limit the upward movement of the road wheels. On the inside of the vertical armor plates, shafts are welded for spring dampers (springs) of the road wheel suspensions. Between the shafts for damping springs of suspensions of the 2nd and 3rd pairs of road wheels, on the sides of the fighting compartment section, there are compartments for the front – lower and upper, side fuel tanks, between the shafts for damping springs of suspensions of the 3rd and 4th pairs track rollers, on the sides of the power plant section, are equipped with compartments for medium fuel tanks. Behind the shafts of shock-absorbing springs of the 5th pair of road wheels, compartments for aft fuel tanks are equipped. Fuel compartments are closed from the inside of the tank by vertical bulwarks made of sheet steel.

Hull feed. It consists of upper and lower stern sheets and final drive housings.

The upper stern sheet, removable, is bolted to the side sheets and can be folded back on hinges. In the middle part of this sheet there is a round hatch for access to the power transmission (transmission compartment units), closed by a lid on hinges and bolts, and on the sides there are two oval holes for exhaust pipes, protected from the outside by armor caps and brackets with locks for attaching smoke checkers. The wires to the electric fuses of the smoke bombs are carried out in steel protective tubes fixed on the upper stern sheet.

The bottom of the hull. In the bottom of the hull there are: hatches for access to the parts of the suspension, to the drain plugs of the tanks and the gearbox housing; hatch for access to the water and oil pumps of the engine; in front of the bottom, on the right, there is a hatch for the crew to leave the tank in conditions where the situation does not allow exit through the upper hatches. On the inside of the bottom of the hull, brackets are installed for attaching the units of the power plant and power transmission, as well as the seats of the driver and machine gunner.

Hull roof. It consists of three parts: the roof of the fighting compartment; roofs of the power plant compartment; power transmission roof.

The roof over the fighting compartment (turret sheet) is welded to the front and side sheets, has a cutout with a diameter of 1600 mm. On the inside, along the perimeter of the linear cutout, an annular body of a tower ball bearing is welded.

Hatches are made in the roof above the fighting compartment: in the corners, hatches above the shafts for suspension springs of the 2nd and 3rd pairs of road wheels; in front, on the right and on the left – two round hatches for access to the plugs of the filler necks of the front and middle fuel tanks. All hatches are closed with armored covers.

The roof of the power plant compartment, removable, is bolted to the side sheets and partitions, consists of a middle sheet located above the engine, having a hatch for access to the engine and two side sheets with air intakes closed by shutters made of armor plates. The blinds are controlled from the fighting compartment. Each air inlet is closed by an armor cap with cutouts for air passage. Through these cutouts and air intake, air is sucked in by the fan and used to cool and power the engine. In the side sheets of the roof of the power plant compartment, two hatches are made above the shafts for the suspension springs of the 3rd and 4th pairs of road wheels and one hatch each for approaching the oil tank fillers. All hatches are closed with armored covers.

In the roof of the power transmission compartment, air outlet shutters are installed, closed with a mesh. The blinds are controlled from the fighting compartment. On the right side of the roof of the power transmission compartment, a hatch is made, closed with an armored cover, for access to the filler neck of the aft fuel tanks.

Gun turret of the T-34-85 tank

In October 1943, in order to speed up work on linking the 85 mm gun in the turret of the T-34 tank, on the initiative of V. A. Malyshev, the turret group of plant No. 183, headed by Nabutovsky, was sent to the TsAKB. Nabutovsky arrived at Malyshev, and he ordered to organize a branch of the Design Bureau of Plant No. 183 at the artillery plant, at which Grabin’s TsAKB worked. After a short collaboration with Grabin, Nabutovsky was sent to the Design Bureau of F. F. Petrov.

In October 1943, in order to speed up work on linking the 85 mm gun in the turret of the T-34 tank, on the initiative of V. A. Malyshev, the turret group of plant No. 183, headed by Nabutovsky, was sent to the TsAKB. Nabutovsky arrived at Malyshev, and he ordered to organize a branch of the Design Bureau of Plant No. 183 at the artillery plant, at which Grabin’s TsAKB worked. After a short collaboration with Grabin, Nabutovsky was sent to the Design Bureau of F. F. Petrov.

As a result, a joint conclusion was made that in order to install the S-53 and D-5 guns on the T-34 tank, a new, more spacious turret with a broadened shoulder strap is required.

- A. Nabutovsky at a special meeting in the presence of D. F. Ustinov, Ya. N. Fedorenko and V. G. Grabin made a counter proposal to design new towers for the T-34 tank for arranging S-53 and D-5T guns in them, based on the design of the turret of an experimental medium tank T-43, the project of plant No. 183. M. A. Nabutovsky criticized V. G. Grabin’s idea. From the speech of M. A. Nabutovsky: “Of course, it would be very tempting to put a new gun in a tank without significant alterations. This solution is simple, but absolutely unacceptable for the reason that with such an installation of the gun, its fastening will turn out to be weak, a large unbalanced moment will arise. In addition, this creates cramped quarters in the fighting compartment and significantly complicates the work of the crew. Moreover, when shells hit the frontal armor, the gun will fall out. Nabutovsky said:”By accepting this project, we will bring the army down.”

The ensuing silence was broken by Grabin: “I am not a tanker, and I cannot take into account everything. And for the implementation of your project, it will take a lot of time, a decrease in production. Ustinov asked: “How long does it take to submit the design bureau of plant No. 183 for approval at this meeting?” Nabutovsky asked for a week, the director of plant No. 112, K. E. Rubinchik, provided him with all his design bureaus. Ustinov also scheduled the next meeting in three days. A. A. Moloshtanov came to the aid of M. A. Nabutovsky.

When designing, the 3-seat turret of an experimental T-43 medium tank was taken as a basis. The design of the turrets was started simultaneously by the Design Bureau of Plant No. 122 “Krasnoe Sormovo” headed by V. V. Krylov for the 85 mm D-5T gun, and the turret group of Plant No. 183 headed by A. A. Maloshtanov and M. A. Nabutovsky for 85 mm S-53 guns. Within three days of round-the-clock work, the technical documentation for the new turret for the S-53 gun was ready. As a result, two new turrets were developed for the T-34 tank, very similar to each other, reminiscent, but not copying the turret of the experimental T-43 tank, with a shoulder strap diameter of -1600 mm.

An order was issued to the TsAKB (Chief Designer V. G. Grabin) “On the development of a special 85-mm gun for the T-34 tank”.

In October 1943, the D-5T gun was tested on the T-34 tank – in a new turret developed by plant No. 112. For better balancing, the gun trunnions were significantly moved forward, however, the breech of the gun was located very close to the stern sheet tower, which made it difficult for the loader. Even when the tank was moving at low speed, trained loaders could not avoid collisions between the head of the projectile and the breech of the gun. The D-5T gun took up a lot of space, so only two people could be accommodated in the new turret. As a result, the D-5T gun was not accepted into service with the T-34 tank.

In October-November 1943, following the order of the NKV to create an 85-mm gun for the T-34 tank, TsAKB and Plant No. 92 produced three prototypes of new tank guns: S-53, (leading designers of the TsAKB: T. I. Sergeev, G. I. Shabarov); S-50, (leading designers of the TsAKB: V. D. Meshchaninov, V. A. Tyurin, A. M. Volgaevsky); LB-1 (LB-85), (factory No. 92, designer A. I. Savin). During the tests, which lasted until the end of the year, preference was given to the S-53 gun. The S-53 gun favorably differed in its simplicity of design, reliability and compactness, it made it possible to accommodate three crew members in a new, more spacious turret. The recoil brake and knurler are located under the base of the bolt, which made it possible to reduce the height of the line of fire and increase the distance between the breech and the rear wall of the tower. The production cost of the S-53 gun turned out to be even lower than for the 76-mm F-34 gun, not to mention the D-5T.

In early December, 1943, Plant No. 122 sent two experimental T-34 tanks, with new turrets, to the Moscow Artillery Plant, where they installed S-53 guns and conducted mostly successful tests, during which flaws appeared in its designs. In this regard, at the artillery plant number 92, during the next meeting, with the participation of: D. F. Ustinov, V. A. Malyshev, B. L. Vannikov, Ya. N. Fedorenko, F. F. Petrov, V. G. Grabin and others, it was decided, for now, to put the D-5T cannon on the “Sormovo” T-34 tanks and at the same time refine the S-53 cannon.

Serial production of the S-53 cannon was supposed to be deployed at factory No. 92, from March 1, 1944, and until then, factory No. 5T.

According to the plan, plant No. 112 was supposed to produce 100 units of T-34 tanks with a D-5T gun by the end of 1943, that is, before the official adoption of the T-34 tank with an 85-mm gun in a new turret into service. However, the first cars were produced only at the beginning of January 1944.

Plant No. 112 “Krasnoye Sormovo” was asked to: ensure the production of T-34-85 tanks with a D-5T gun in quantities:

- In January 1944 – 25 units;

- In February 1944 – 75 units;

- In March 1944 – 150 units;

- From April 1944 – completely switch to the production of T-34-85 tanks, instead of T-34-76.

On January 1, 1944, the S-53 gun was adopted by the T-34 tank, both with standard (1420 mm) and extended (1600 mm) shoulder straps. Moloshtanov and Nabutovsky, with all the documentation on the layout of the new S-53 gun in the new turret, for the T-34 tank, arrived at plant No. 183.

The design of the tower with the gun S-53 (ZIS-S-53)

The T-34-85 turret, developed on the basis of the turret design for the experimental medium T-43, was five-sided, with rounded ribs, and had armor thickness increased to 90 mm in the frontal part. For some reason, Soviet tankmen attributed the configuration of the T-34-85 tank turret to the Conical category, and the T-54 tank turret to the Hemispherical category.

The T-34-85 turret, developed on the basis of the turret design for the experimental medium T-43, was five-sided, with rounded ribs, and had armor thickness increased to 90 mm in the frontal part. For some reason, Soviet tankmen attributed the configuration of the T-34-85 tank turret to the Conical category, and the T-54 tank turret to the Hemispherical category.

When creating the new D-5T tank gun and the S-53, which won the competitive tests, the ballistics of the 85 mm 52-K anti-aircraft gun of the 1939 model was taken as the basis. During test firing, which took place from April 25 to April 30, 1943 at the NIIBT training ground in Kubinka, the 52-K anti-aircraft gun pierced 100 mm of the frontal armor of the captured Tiger from a distance of 1000 m. In addition, the development of a new tank gun based on the 52-K anti-aircraft gun, reduced the time to master the production of shells.

In fact, the configuration of the tower body is formed by a frontal, rounded, embrasure part, five flat inclined faces, mating linear surfaces of variable radius, and a flat, horizontal hexagonal roof.

- The tower is cast, hexagonal in plan, with inclined side walls. In the front wall, a loophole for installing a gun is cut out, closed by swinging armor.

Technologically, the tower is divided into three parts: running part; body part; the roof of the tower, connected to each other, along the perimeters, by welded seams.

The running part (upper turret shoulder strap) is a large-sized casting, cylindrical at the bottom, conjugated, in its upper part, with a hexagonal base for mounting the body part.

The cylindrical part serves as a holder for the support ring of the upper shoulder strap of the ball bearing welded into it. p.54.

The body part is a large-sized casting, formed by the frontal (embrasure) part, (thickness 90 mm) and 5 inclined flat faces (walls): two front – side, (thickness 75 mm, slope 20 °); two rear – side, (thickness 75 mm, slope 20 °) and one stern face, (thickness 52 mm, slope 10 °), conjugated with each other radius fillets. An embrasure window

is formed in the frontal part, for installing a gun, closed by a swinging armor protection (mask) of the gun. From the inside, brackets with tides are welded to the frontal part, to which horizontal trunnions for the gun cradle are bolted. On the left bracket there is a stopper for attaching the gun “On the march”, and the lifting mechanism of the gun. p.54.

In the side walls of the tower there are loopholes for firing from personal weapons, closed by armor plugs. Outside, on the side walls of the tower, welded: handrails for paratroopers; mounting hooks or brackets – “rings”. On the aft wall of the tower, outside, fastenings for a tarpaulin are welded.

Turret roof: flat, hexagonal, cut from a flat armor plate (20 mm thick). Hatch cutouts are made in the roof:

– for the installation of two periscope observation devices, for the loader and the gunner;

– ventilation, for the installation of two fans of the fighting compartment, closed by armored caps with windows for the passage of air;

– antenna output;

– a hatch for the entrance and exit of the loader and gunner;

— cutout for the installation of the commander’s cupola.

Command tower. Serves to provide an all-round view to the tank commander. Cylindrical, cast from armor and welded along the perimeter to the roof of the gun turret. Five slits are made in the walls of the turret, covered with transparent armored glass “triplex “, through which, with the help of viewing devices, the commander makes a circular view, both with a rotating and stationary gun turret. The roof of the turret rotates on a ball bearing. On its roof, a tank commander’s hatch is made and a periscopic observation observation device is installed, similar to the devices installed on the roof of the gun turret. p.54.

Due to the individual characteristics of the production of different factories, and depending on the time of production, the turrets, T-34-85 tanks equipped with S-53 and ZIS-S-53 guns differed in: the number, configuration and location of molding and welds; the shape of the commander’s turret (in January 1945, only a single-leaf hatch cover of the commander’s turret was put into production); the shape and location of the protective strips of the turret. The post-war towers of plant No. 112 had a spaced arrangement of ventilation hoods, the front fan was an exhaust fan, and the rear one was a pressure fan. –>

The layout of the tower with the gun S-53 (ZIS-S-53)

Inside the turret, the main armament of the tank is installed: a cannon and one machine gun coaxial with it. The vertical aiming of the gun is done manually, using a sector lifting mechanism located to the left of the gun. The vertical angle of elevation of the gun is 22°. The vertical angle of descent is 5°, while the unaffected (dead) space for the cannon and coaxial machine gun on the ground is 23 meters. The height of the gun line of fire is 2020 mm. The rotation of the tower is carried out by a turning mechanism located to the left of the gun, using a manual drive, with an angular velocity of 0.9 ° per revolution of the flywheel or electromechanical drive, with an angular velocity of 25-30 ° / sec. In the aft niche and on the racks there is the main stack for sixteen (on some machines – twelve) shots. On the right wall of the tower, in clamps, 4 shots are fixed. To ensure the rollback of the gun after the shot, free space is provided behind the breech. Inside the turret, on the left side, the following are reinforced: a bracket for the turret rotation mechanism and mounts for the radio station and tank intercom devices (TPU). Inside the tower, on the left rear and aft walls, there are brackets for mounting the transceiver and the power supply of the radio station. Attached to the tower, rotate with it, the seats: tank commander; gunner and loader. The loader’s seat is suspended on three straps, two of them are attached to the turret ring, and the third to the gun cradle. Seat height adjustment is made by changing the length of the straps. The tower does not have a floor that rotates with it, which is attributed to its design flaw. When firing, the loader worked standing on the covers of the cassette boxes with shells laid on the bottom of the hull. When turning the tower, he is forced to move after the breech of the gun, kicking the fallen spent cartridges with their feet, which, when conducting intense fire, accumulated and made it difficult to access the shots placed in the ammunition rack on the bottom of the hull. pp. 53-59.

Armament

| Ammunition gun S-53 | |||||||||

| Ammo Type | projectile type | Projectile brand | Shot mass, kg | Projectile weight, kg | Mass of explosives, g | Fuse brand | Muzzle velocity, m/s | Range of a direct shot at a target with a height of 2 m | Year of adoption |

| Armor-piercing shells | |||||||||

| UBR-365 | armor-piercing blunt-headed with a ballistic tip, tracer | BR-365 | 16.00 | 9.20 | MD-5 or MD-7 | 800 | 950 | ||

| UBR-365K | armor-piercing sharp-headed, tracer | BR-365K | 16.20 | 9.34 | MD-8 | 800 | 900 | ||

| UBR-367 | armor-piercing sharp-headed with protective and ballistic tips, tracer | BR-367 | DBR-2 | post-war period | |||||

| UBR-365P | armor-piercing sub-caliber reel type, tracer | BR-365P | 11.42 | 4.99 | — | — | 1050 | 1100 | 1944 |

| UB-367P | armor-piercing streamlined sabot, tracer | BR-367P | 11.72 | 5.35 | — | — | 1024 | 1140 | post-war period |

| High-explosive shells | |||||||||

| UO-365K | steel one-piece anti-aircraft fragmentation grenade | O-365 | 16.30 | 9.54 | 660 | T-5 or KTM-1 or KTMZ-1 | 793 | ||

| UO-365K | steel fragmentation grenade with adapter head | O-365K | 16.30 | 9.54 | 741 | KTM-1 | |||

| UO-367 | steel solid-body fragmentation grenade, with a reduced charge | O-365K | 9.54 | 741 | KTM-1 or KTMZ-1 | ||||

| Practical projectiles | |||||||||

| UPBR-367 | practical solid, tracing | PBR-367 | — | — | |||||

| Armor penetration table for S-53 | ||||||

| Projectile \ Distance, m | 100 | 300 | 500 | 1000 | 1500 | 2000 |

| BR-365 | ||||||

| (meeting angle 90°) | 119 | 115 | 111; 105 | 102; 100 | 93; 92 | 85 |

| (meeting angle 60°) | 97 | 93 | 91; 90 | 83; 85 | 76; 78 | 69; 72 |

| BR-365K | ||||||

| (meeting angle 90°) | 126 | 118 | 110; 108 | 95; 102 | 75; 90 | 65; 82 |

| (meeting angle 60°) | 103 | 96 | 90 | 75; 78 | 65; 72 | fifty; 66 |

| BR-365P | ||||||

| (meeting angle 90°) | 167 | 152 | 140 | 110 | 85 | — |

| (meeting angle 60°) | 124 | 114 | 100 | 80 | 60 | |

| It should be remembered that at different times and in different countries, different methods for determining armor penetration were used. As a result, direct comparison with similar data from other tools is often impossible. | ||||||

Means of observation and communication

The gunner for aiming at the target had: – a telescopic sight TSh-16 (4x magnification, field of view 16 °) as well as a side level for firing from closed positions. The commander for detecting targets had: – an MK-4 periscope observation device in the commander’s cupola. As a backup, there were 5 sighting slots in the commander’s cupola. The gunner had: – an MK-4 periscope observation device in the roof of the tower. The shooter for firing from the course 7.62-mm machine gun DT used: – PPU-8T telescopic sight. The driver was observing through: – 2 periscope observation devices in the hatch cover.

The means of communication consisted of a 9RS transceiver radio station (the range of the microphone on the move is 18 – 20 km, in the parking lot – 28 -32 km) and an internal intercom TPU-3-BIS-F. In addition, light and flag signaling was possible.

Electrical equipment

The mains voltage 12/24 V was provided by 4 batteries with a total capacity of 128 Ah. Electric generator GT-4563A, shunt, 1000 W with relay-regulator RRA-24F. Serial starter ST-700 with a power of 15 hp at a supply voltage of 24 V. The electric motor of the fan located under the roof of the tower is MV-12, shunt, with a power of 19 W at a voltage of 12 V. The electric motor for turning the tower is MB-20K, serial, with a power of 1350 W at a voltage of 24 V.

Engine and transmission

The T-34-85 tank was equipped with a 12-cylinder four-stroke uncompressed diesel V- 2-34. The rated power of the engine was 450 hp. With. at 1750 rpm, operational – 400 l. With. at 1700 rpm, maximum – 500 l. With. at 1800 rpm. Maximum torque 2200 Nm at 1150 rpm. Cylinder diameter 150 mm. The stroke of the pistons of the left group is 180 mm, the right one is 186.7 mm. The cylinders were arranged in a V-shape at an angle of 60°. The compression ratio is 14 – 15. The working volume of all cylinders is 36.8 liters. The weight of a dry engine with an electric generator without exhaust manifolds is 750 kg. Fuel – diesel, grade DT or gas oil grade “E” according to OST 8842.

Specific fuel consumption in operating mode – 170 g / hp.h., specific oil consumption in operating mode – 13 g / hp.h. Specific power – 15.02 hp / t.

Fuel tank capacity – 545 l. Outside, on the sides of the hull, two fuel tanks of 90 liters each were installed. External fuel tanks were not connected to the engine power system. The fuel supply is forced, using a twelve-plunger fuel pump NK-1. The lubrication system is circulating, under pressure. Oil circulation was carried out by a gear three-section oil pump. The capacity of the internal oil tanks is 76 liters, the external one is 90 liters. The cooling system is liquid, closed, with forced circulation. Radiators – two, tubular, installed on both sides of the engine with an inclination towards it. Radiator capacity – 95 l. To clean the air entering the engine cylinders, two Multicyclone air cleaners were installed on the tank. The engine was started by an electric starter ST-700 with a capacity of 15 liters. With. were installed in the management department). The transmission consisted of a multi-disk main clutch of dry friction (steel on steel), a gearbox (capacity 11 l ), steering clutches, brakes and final drives. Gearbox – five-speed, with constant meshing gears. Side clutches are multi-disc, dry (steel on steel), brakes are floating, band, with cast-iron pads. Final drives are single-stage.

Chassis

The undercarriage of the T-34-85 tank, in relation to one side, consisted of five double rubber-coated road wheels with a diameter of 830 mm. Suspension – individual, spring.

The rear drive wheels had six rollers for engagement with the ridges of the caterpillar tracks.

The guide wheels are cast, with a crank mechanism for tensioning the tracks.

Caterpillars – steel, small-link, with ridge engagement, 72 tracks in each (36 with a ridge and 36 without a ridge). Track width 500 mm, track pitch 172 mm. The mass of one caterpillar is 1150 kg.

Combat use

The Great Patriotic War

Despite a number of very serious improvements to the T-34, its combat performance in the second half of the war could not be considered completely satisfactory against the backdrop of improvements in German tanks and anti-tank weapons.

Despite a number of very serious improvements to the T-34, its combat performance in the second half of the war could not be considered completely satisfactory against the backdrop of improvements in German tanks and anti-tank weapons.

Less vulnerable in 1941 to almost any German tanks and anti-tank weapons (even in the old version, more poorly armed and armored), the T-34 at the end of the war was no longer able to withstand heavy German tanks and assault guns on an equal footing, which still did not have an absolute advantage in all combat situations. In addition, they belonged to a different class in terms of mass, high cost of production, often lost in mobility, not to mention their quantitative shortage and technological difficulties at the end of the war, which affected, for example, the quality of their armor. The lack of major changes in armor left the tank insufficiently protected from German infantry anti-tank weapons.the final period of the war, of course, counted on the fight against the massive T-34. A very serious problem was the appearance by that time of anti-tank rocket-propelled grenade launchers, although German tanks suffered no less from the fire of American bazooka -type grenade launchers. As a result, in 1945, approximately 90% of hits on the T-34 led to armor penetration. This had to be compensated for by their massive and competent use, moreover, the leading role in the fight against enemy tanks was largely transferred to heavy tanks, such as the IS-2, and self-propelled guns; nevertheless, the T-34, while remaining the Soviet main tank, played an invaluable positive role in the second half of the war, which is partly due to improved command and control of tank troops, better interaction with other branches of the military, especially with aviation, as well as very good mobility and remaining all the same quite decent armor and firepower. The reliability of the tank, which had increased by this time, and, of course, the mass production, also played an important role. By the end of the war, the T-34 was the most numerous tank in the Soviet army. It was the T-34-85, competently acting from an ambush, that successfully hit the first “King Tigers” in the side armor in the battle near Oglenduv.

The most successful T-34-85 tanker was Bochkovsky Vladimir Aleksandrovich, he accounted for 36 destroyed German tanks. A large number of tanks, combined with their mobility, made any direction tank- dangerous, forcing the enemy to spend huge resources on mining, anti-tank guns (batteries), infantry PTS (in each battalion) across the entire width of the front. Mass tanks, however, always retained the possibility of a concentrated strike and the development of a breakthrough with a large number of their own guns, machine guns, infantry and artillery deployed under their armored cover.

The most successful T-34-85 tanker was Bochkovsky Vladimir Aleksandrovich, he accounted for 36 destroyed German tanks. A large number of tanks, combined with their mobility, made any direction tank- dangerous, forcing the enemy to spend huge resources on mining, anti-tank guns (batteries), infantry PTS (in each battalion) across the entire width of the front. Mass tanks, however, always retained the possibility of a concentrated strike and the development of a breakthrough with a large number of their own guns, machine guns, infantry and artillery deployed under their armored cover.

Korean War

After the Second World War, the T-34-85 was actively exported to many countries of the world and was used in a number of military conflicts. Tanks remained in service with some countries, such as Iraq, until the end of the 20th century.

Korean War (1950-1953, China, North Korea). The war in Korea was a real test for the T-34 crews, who had to operate under enemy air supremacy against well-equipped anti-tank weapons of the American army and marines. North Korean T-34-85s were used most intensively in the first two months of the war. The Americans responded by deploying about 60 M24 Chaffee tanks in four companies to Korea. The first battles revealed the inability of American M24 tanks and bazooka grenade launchers”pierce the armor of “thirty-fours”. The defeat of the Smith Company was indicative, as well as the death of Colonel Bob Martin, commander of the 34th US Infantry Regiment. On July 8, in the city of Chonan, the commander of the 34th regiment ran out to meet the T-34-85 and fired from a bazooka, which did not harm the tank; in response, the colonel received a direct hit from an 85-mm projectile. According to the Americans, more than 100 US soldiers were killed during a tank assault in Chonan on July 8. After that, requests began to arrive for “super bazookas” and heavier tanks. New weapons arrived in huge quantities, and in a short time the United States provided a multiple numerical advantage in anti-tank weapons. In one battle on the Incheon-Seoul road, the marines, supported by tanks “Pershing”, destroyed 6 T-34-85 and killed 200 North Korean soldiers, while losing 1 soldier wounded. On September 21, during the Inchon landings, T-34-85s killed another high-ranking American commander, Colonel Henry Hampton, a unit commander of the 7th Infantry Division. After suffering heavy losses from modern weapons, the participation of the T-34-85 in battles was rarely noted and only in small groups of 3-4 tanks. Chinese troops also used T-34-85 tanks.

In total, the North Koreans used about 410 T-34-85 tanks during the war, including 258 at the beginning of the war and another 150 were received during the war. The Chinese used about 320 T-34-85 and IS-2 tanks during the Korean War. In particular, the 3rd and 4th tank regiments of the 2nd tank division each had 30 T-34-85 tanks.

Over the entire period of the war, there were 119 tank battles with North Korean tanks, of which 104 were carried out by US Army tanks and another 15 by USMC tankers. During these battles, North Korean tankers on the T-34-85 managed to knock out at least 34 American tanks (16 M4A3E8 Sherman, 4 M24 Chaffee, 6 M26 Pershing and 8 M46 Patton), 15 of which were lost forever. In addition, there were losses from the fire of tanks T-34-85 of the PRC army, only tanks of the 3rd and 4th regiments destroyed 21 and knocked out 7 American tanks, and in total, according to Chinese data, tank units (including IS-2 and Su-76) destroyed 146 and knocked out 35 enemy armored vehicles. According to researcher S. Zaloga, from the beginning of the war until the end of autumn 1950, 97 T-34s were shot down by American tankmen in battles (some were repairable), and another 18 tanks were declared presumably knocked out 34. According to other American data (Operations Research Office), which refers to official data from the US Department of Defense, during the same period (until the end of autumn 1950), 39 T-34-85s were hit by American tank fire. The total loss of North Korean T-34-85s from all causes during this period amounted to 239 vehicles. The total losses of the “thirty-fours” in Korea for the entire war are unknown.

American pilots claimed to have inflicted huge losses on the T-34-85. So the pilots reported that almost 3,000 North Korean tanks were disabled, as Steven Zaloga pointed out, this number was many times greater than the number of tanks in general available to North Korea. Zaloga also indicated during the identification and verification until April 1952, 296 disabled T-34-85s were seen in the theater of operations. Against the background of this fact, the incident that occurred on July 3, 1950, when the four F-80C Shooting Star jet fighter-bombers, led by the commander of the 80th Ibae, Mr. Amos Sluder, went to the Pyeonggyo-Ri area to attack enemy vehicles moving towards the front line. Having found a convoy of about 90 vehicles and tanks, the Americans went on the attack, using unguided rockets and fire from onboard 12.7-mm machine guns from a low altitude. An unexpected response came from the North Korean T-34s, which opened fire on the low-flying aircraft with their 85mm guns. A successfully fired projectile exploded in front of the leader’s aircraft and damaged the fuel tanks with fragments, a fire broke out on board. Walking as a wingman, Mr. Verne Peterson told Major Sluder by radio: “Boss, you are on fire! You better jump.” In response, the commander asked to indicate the direction to the South, where he was going to continue to pull, but at the same moment the plane collapsed and fell to the ground like a burning torch..

American pilots claimed to have inflicted huge losses on the T-34-85. So the pilots reported that almost 3,000 North Korean tanks were disabled, as Steven Zaloga pointed out, this number was many times greater than the number of tanks in general available to North Korea. Zaloga also indicated during the identification and verification until April 1952, 296 disabled T-34-85s were seen in the theater of operations. Against the background of this fact, the incident that occurred on July 3, 1950, when the four F-80C Shooting Star jet fighter-bombers, led by the commander of the 80th Ibae, Mr. Amos Sluder, went to the Pyeonggyo-Ri area to attack enemy vehicles moving towards the front line. Having found a convoy of about 90 vehicles and tanks, the Americans went on the attack, using unguided rockets and fire from onboard 12.7-mm machine guns from a low altitude. An unexpected response came from the North Korean T-34s, which opened fire on the low-flying aircraft with their 85mm guns. A successfully fired projectile exploded in front of the leader’s aircraft and damaged the fuel tanks with fragments, a fire broke out on board. Walking as a wingman, Mr. Verne Peterson told Major Sluder by radio: “Boss, you are on fire! You better jump.” In response, the commander asked to indicate the direction to the South, where he was going to continue to pull, but at the same moment the plane collapsed and fell to the ground like a burning torch..

At the end of the war, parts of the DPRK and the PRC were armed with 533 T-34-85 and 38 IS-2 tanks, the UN troops had twice as many about 1100 vehicles.

Operation at the Bay of Pigs

Cuban T-34-85s saw action in the Bay of Pigs in 1961. The invading troops had 10 M41 tanks and 20 M8 armored cars.

The landing began on April 17, by noon an infantry regiment, a tank battalion (about 20 T-34-85 tanks ) and a division of 122-mm howitzers advanced to the landing site.

Fidel Castroarrived at the position for direct command of the troops. In the evening, the Milicianos, with the support of several T-34-85 tanks that arrived in time, tried to advance in the direction of Playa Larga. Unable to turn around in the swampy terrain, the tanks moved in a column along the highway, preventing each other from firing. “Gusanos” let them get closer and knocked out the lead “thirty-four” of three “Bazookas”. The Cubans retreated. April 18, after artillery preparation, the Cuban army went on the offensive. By 10:30 in the morning they took Playa Larga and went ashore, where they attacked landing craft trying to approach the shore. On April 19, at 17:30, the Cubans stormed the village of Playa Giron, the last point of defense of the “2506 brigade”. The first to enter the village was a company of T-34-85 tanks, in the lead vehicle was Fidel Castro himself, who personally led the attack. In Playa Girona, the last two “Bulldogs” of the counter-revolutionaries were hit. During the operation, 5 Cuban T-34-85 tanks were knocked out (1 irrevocably). The counter-revolutionaries lost all their armored vehicles, 5 M41s and 10 M8s were shot down and captured, and the same number drowned in landing craft.

Fidel Castroarrived at the position for direct command of the troops. In the evening, the Milicianos, with the support of several T-34-85 tanks that arrived in time, tried to advance in the direction of Playa Larga. Unable to turn around in the swampy terrain, the tanks moved in a column along the highway, preventing each other from firing. “Gusanos” let them get closer and knocked out the lead “thirty-four” of three “Bazookas”. The Cubans retreated. April 18, after artillery preparation, the Cuban army went on the offensive. By 10:30 in the morning they took Playa Larga and went ashore, where they attacked landing craft trying to approach the shore. On April 19, at 17:30, the Cubans stormed the village of Playa Giron, the last point of defense of the “2506 brigade”. The first to enter the village was a company of T-34-85 tanks, in the lead vehicle was Fidel Castro himself, who personally led the attack. In Playa Girona, the last two “Bulldogs” of the counter-revolutionaries were hit. During the operation, 5 Cuban T-34-85 tanks were knocked out (1 irrevocably). The counter-revolutionaries lost all their armored vehicles, 5 M41s and 10 M8s were shot down and captured, and the same number drowned in landing craft.

Six day war

Used by Egypt and Syria.